Description

Despite the advances of modern technology, a large proportion of polo players still prefer the feel of cane as opposed to composite materials for the shaft of mallets. Each cane has been personally selected by George Wood in Asia and meets with his stringent quality control. They’re made to order in New Zealand.

Canes

A short video from the workshop

As the saying goes, “you can’t make a silk purse out of a sow’s ear”. The selection of raw materials is critical to the performance of what are known by many, to be the best polo mallets in the world.

We’re dedicated to sourcing only the best materials available. Our stringent selection process rejects over 97% of the root ends of canes that are cut from the jungles of Indonesia. The selection process is always done by myself. Mainly due to deforestation, the quality of canes has decreased dramatically over the past few years. Really “good” canes are few and far between. Manau has always been the best cane used for polo mallets but 2019 was the last year this species was available. Inferior species called Batu and Tohiti are now being used by other mallet makers out of necessity. We’ve all seen them, they tend to be thick at the handle, thin at the head and have lots of knots but they have very little strength. As the cost of raw materials continues to rise the future of cane supply is uncertain. We have enough manau cane to see us through 2020 but that’s it!

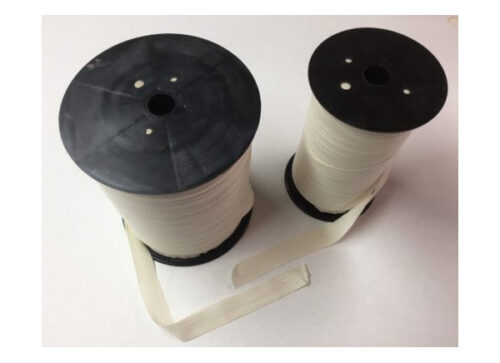

One of the most important stages of manufacturing a cane mallet is seasoning the canes to reduce the moisture content and temper the shaft so that it reaches its optimum tension while retaining its ‘memory’. This is done over a long period of time using a low temperature oven and regular straightening. After cutting to the required lengths the handles are fitted and an epoxy resin binding is applied to the shaft just above where the head is fitted. This is allowed to set before being ground smooth and the traditional cotton tape binding is applied over the top. Although this takes considerable time and expense, it adds tremendous extra strength to the mallets most vulnerable area, almost eliminating ‘wringers’. Just another example of the extra lengths we go to guarantee performance.

Custom Made

Every aspect of the mallet may be custom made exactly to the customer’s requirements at no extra charge. The handles are available in a range of sizes: small, medium, large, and extra large. Unless specified, the slings are kept at 19 1/2″ long. Black rubber grip material is used for the grips.

The art of a mallet maker is to match the tension and weight of each cane to exactly the right weight head to produce the perfect balance that makes the mallet feel like a natural extension of the arm. Having played polo around the world for for over 4 decades, I’m well aware of this requirement.